Shandong kerui petroleum technology co.,ltd. assist the construction of national natural gas storage

Update time:2020-05-13 16:39 views:3249

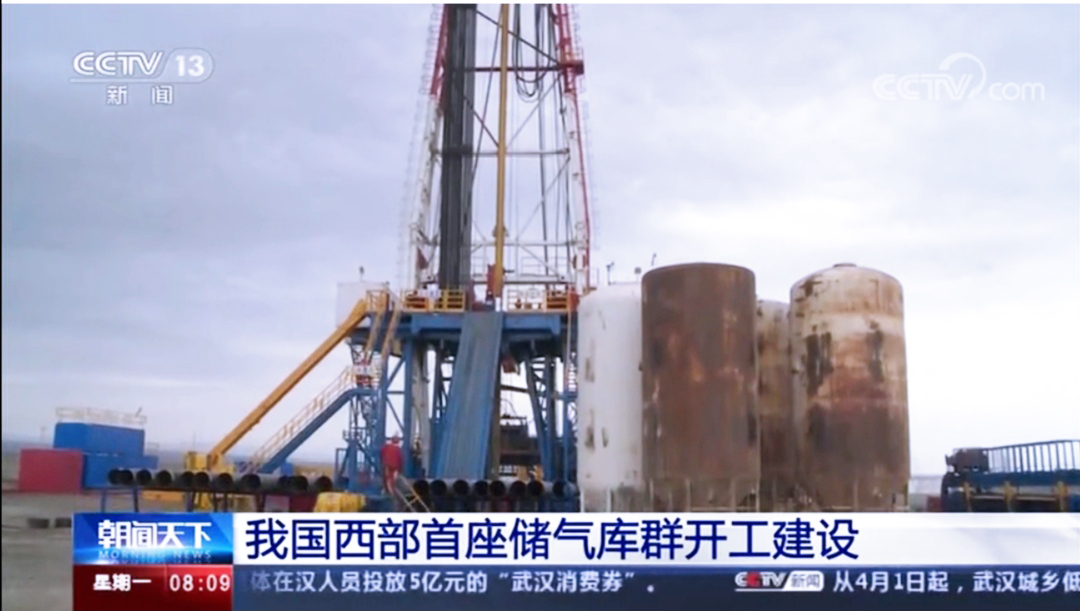

Recently, CCTV “CCTV News” and “Zhaowentianxia” news program successively reported the construction of Wenjisang gas storage project in Tuha oilfield, the first gas storage group in western China.

Tuha oilfield Wenjisang gas storage group is a national important storage construction project, is the first middle-low porosity, middle-low permeability, strong heterogeneity and complex gas reservoir storage group, is also the important auxiliary project in China west to east gas transmission. Shandong kerui petroleum technology co.,ltd. undertake Wenxi-gas storage pilot test injection project of this national important project. The main purpose of operation including: (1)solving gas injection equation and gas production equation, evaluate the gas injection and production capacity of the gas injection and production well; (2) logging the gas injection profile in complex injection, determine the suction capacity of each perforated interval; (3) determine the reservoir connectivity of the well group.

According to the requirments of continuity of gas injection for customer in Tuha oilfield, as well as the demand for improving the reliability of gas injection equation, gas production equation, gas injection and gas production capacity of gas storage, Shandong kerui petroleum technology co.,ltd. carried out comprehensive maintenance on the equipment before construction, prepared sufficient spare parts, and added a set of spare equipment on the basis of the original equipment; aimed at the summer environment of the operation site as high as 53 ℃, targeted development of development of equipment high temperature operation plan; combined with multiple measures, effectively ensure the equipment operation time rate above 99%. In addition, in order to make the nitrogen injection purity above 99.2%, Shandong kerui petroleum technology co.,ltd. adopt the world’s advanced carbon adsorption technology, the air first purified through membrane separation and purification, and then enter carbon adsorption secondary purification to ensure the safety of gas injection.